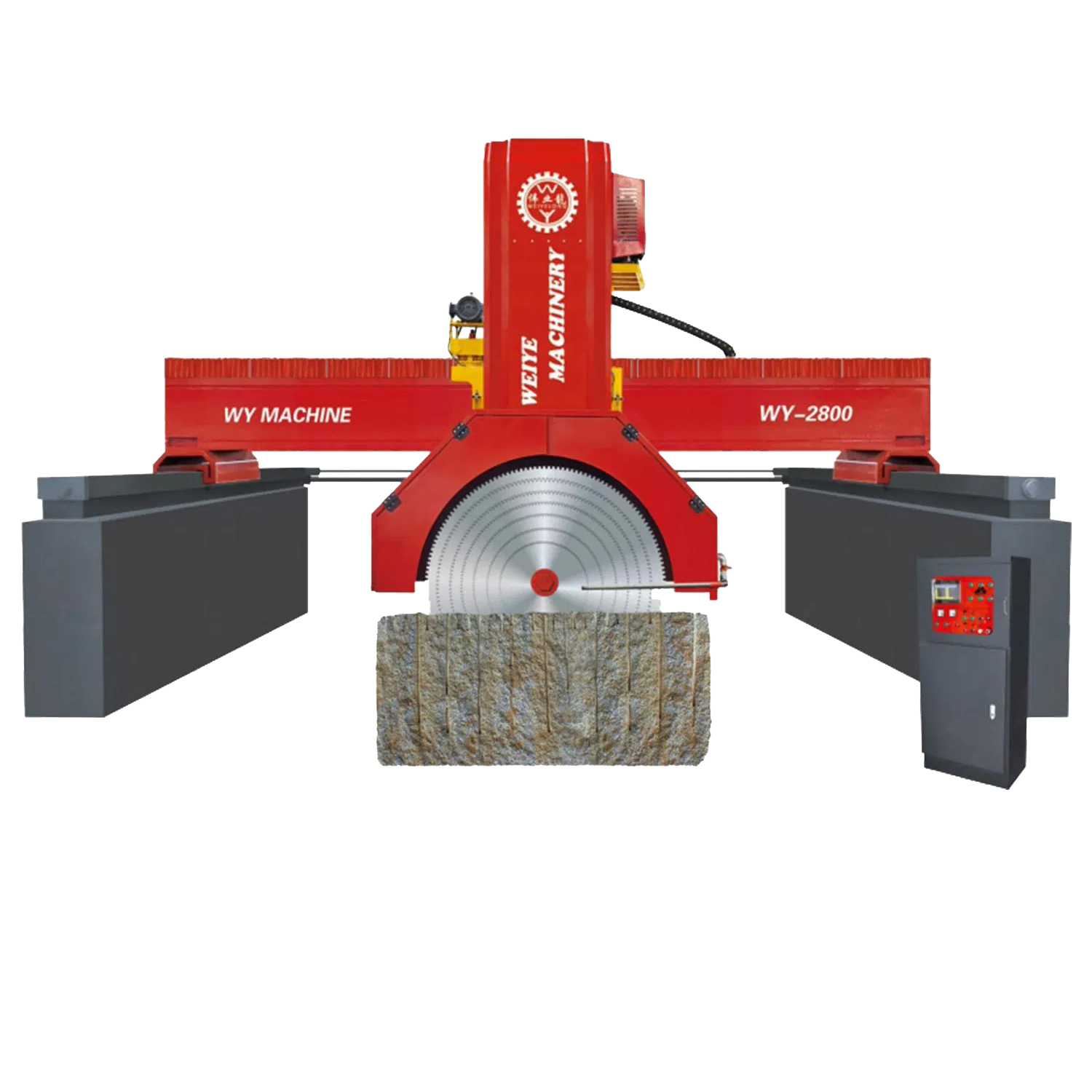

It delivers exceptional cutting accuracy and repeatability for the most demanding stone working applications.

The machine employs an inverter to regulate the lateral feed movement, allowing for speed adjustment based on the stone material characteristics. It incorporates a hydraulic lifting system supported by a combination of chrome-plated guide pins and wear-resistant guide bushes with minimal clearance. The structure is robust and aesthetically designed, featuring multi-layer sealed guide sleeves that provide waterproof, dustproof, and anti-spill properties, significantly enhancing service life.

For forward and backward slicing, a high-precision ball screw drive mechanism ensures fully automatic operation. Key components are manufactured from imported high-quality materials. The worktable can be ground-mounted, eliminating the need for a dedicated base and reducing both initial setup and maintenance costs.

As a result, the machine delivers high cutting efficiency, exceptional slicing accuracy, superior surface flatness, and reliable stability. Its user-friendly design makes it ideal for processing high-value granite and marble blocks.

Advanced PLC System with Human-Machine Interface Innovative Stone Cutting Machine

This state-of-the-art stone cutting machine integrates an Ultra-High

Excogitatum est super his, ut homines quidam ignoti, vilitate ipsa

| Product Name | Unit | WY-2200 | WY-2500 |

| Blade Diameter | mm | Φ2200 | Φ2500 |

| Maximum Lifting Stroke | mm | 1400 | 1400 |

| Maximum machine length | m | 3000 | 3000 |

| Saw Blade Number | pcs | 3-5 | 6-9 |

| Water Consumption | m³/h | 15 | 15 |

| Main Motor Power | kw | 37 | 45 |

| Total Power | kw | 47 | 55 |

lt uses hydraulic lifting system Main spare partsadopt imported good-quality materials.

The process begins with the client specifying the desired type of equipment and budget. The Development Department then evaluates technical and spatial requirements to design a fully customized plant layout. Following this, the Commercial Department assesses project feasibility, prepares a detailed economic offer, and verifies all production costs.

Finally, upon delivery and installation of the equipment, WeiYe’s technical team provides on-site training in machine operation and maintenance, ensuring a smooth and efficient start for the customer.