When it comes to sourcing stone slab polishing machines, China is one of the most competitive and advanced manufacturing hubs in the world. Dozens of factories produce equipment designed for marble, granite, quartz, and other stone materials, ranging from small-scale units to fully automatic production lines.

However, with so many options, choosing the right factory can be challenging. This guide will help you understand what to look for when selecting a reliable stone polishing machine manufacturer in China.

Experience matters in machine manufacturing.

Look for factories with at least 10 years of production experience and a proven track record of exporting to international markets. A company with long-term expertise is more likely to offer stable quality, mature technology, and reliable after-sales service.

Tip: Check the company’s website, certification documents (such as ISO, CE), and video demonstrations of machine operation.

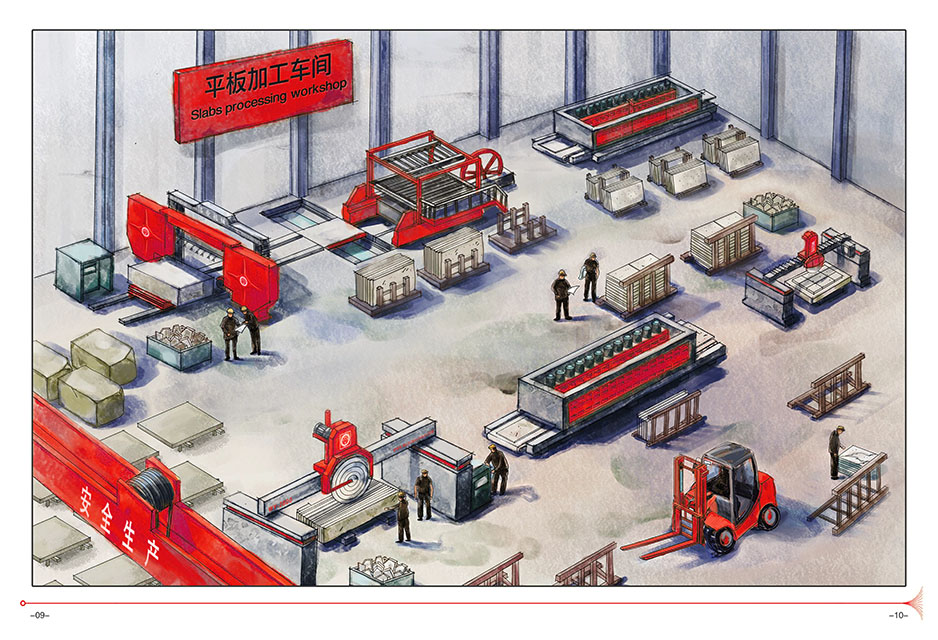

A trustworthy factory usually offers a complete series of stone processing machines, including:

This shows that the factory has a strong R&D and integration capability rather than only assembling low-end models.

Tip: Ask for machine specifications, motor brand, control system type (e.g., Siemens, Delta), and whether it supports wet and dry polishing.

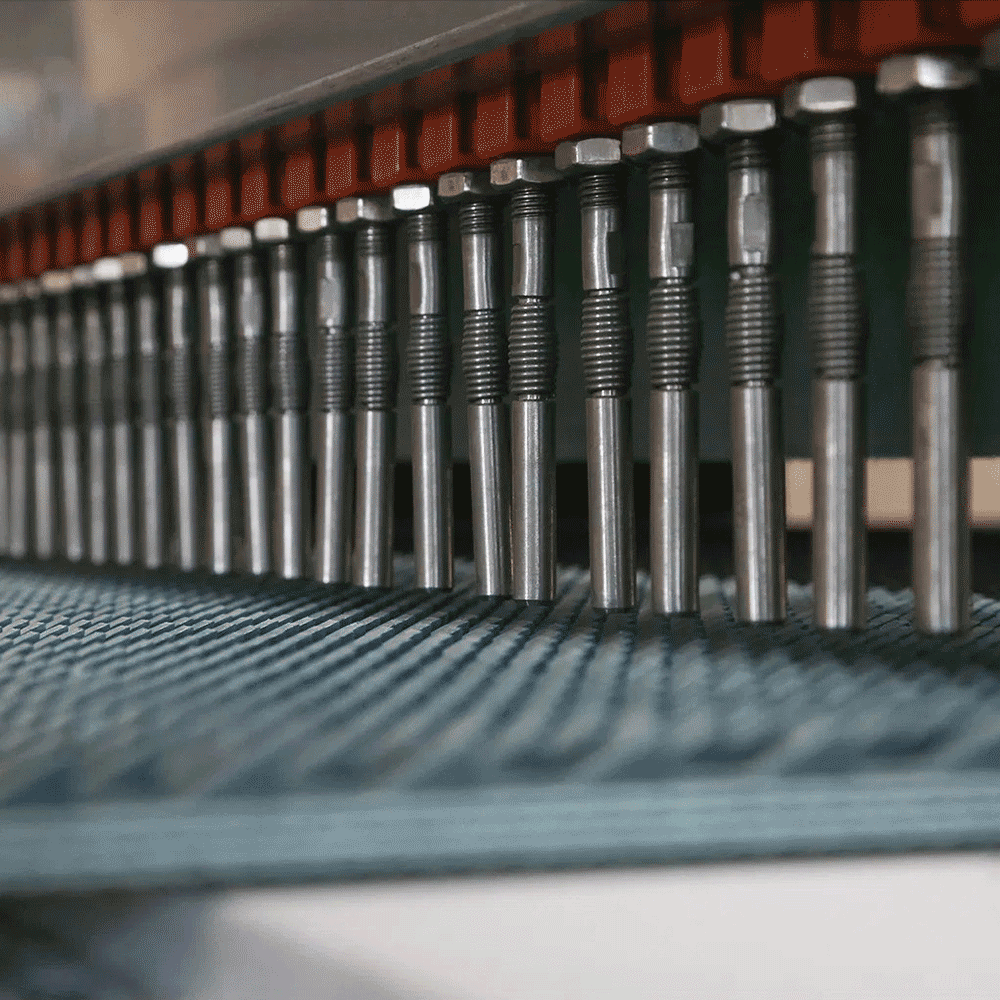

The quality of the polishing head, motor, and control system directly affects performance and lifespan.

Reputable manufacturers use:

If possible, request a video inspection or third-party quality check before shipment.

After-sales service is a crucial factor, especially for overseas buyers.

Choose a manufacturer that provides:

A reliable factory will ensure that you can operate and maintain the machine easily, reducing downtime.

While Chinese manufacturers are known for competitive prices, the cheapest option is not always the best. Focus on value for money — that is, performance, durability, and service support relative to the price.

Tip: Request a detailed quotation including warranty terms, spare parts list, and estimated delivery time.

Whenever possible, conduct an on-site factory visit or hire a third-party inspection agency. This helps verify:

If you cannot visit in person, a live video tour can be a great alternative.

Choosing the right stone slab polishing machine factory in China requires careful consideration of experience, machine quality, technical capability, and after-sales support.

By following the steps above, you can find a reliable manufacturer that delivers durable machines, efficient performance, and strong technical assistance for your business.

If you’re looking for a professional supplier, Weiye Machinery is one of the leading manufacturers in China, offering a full range of stone cutting, polishing, and shaping machines with high precision and stability — trusted by clients worldwide.