Weiye Machinery's African factory ten years ago

Marble slabs are efficiently processed through a fully automated system that begins with a turnover machine placing the slab onto a conveyor belt.

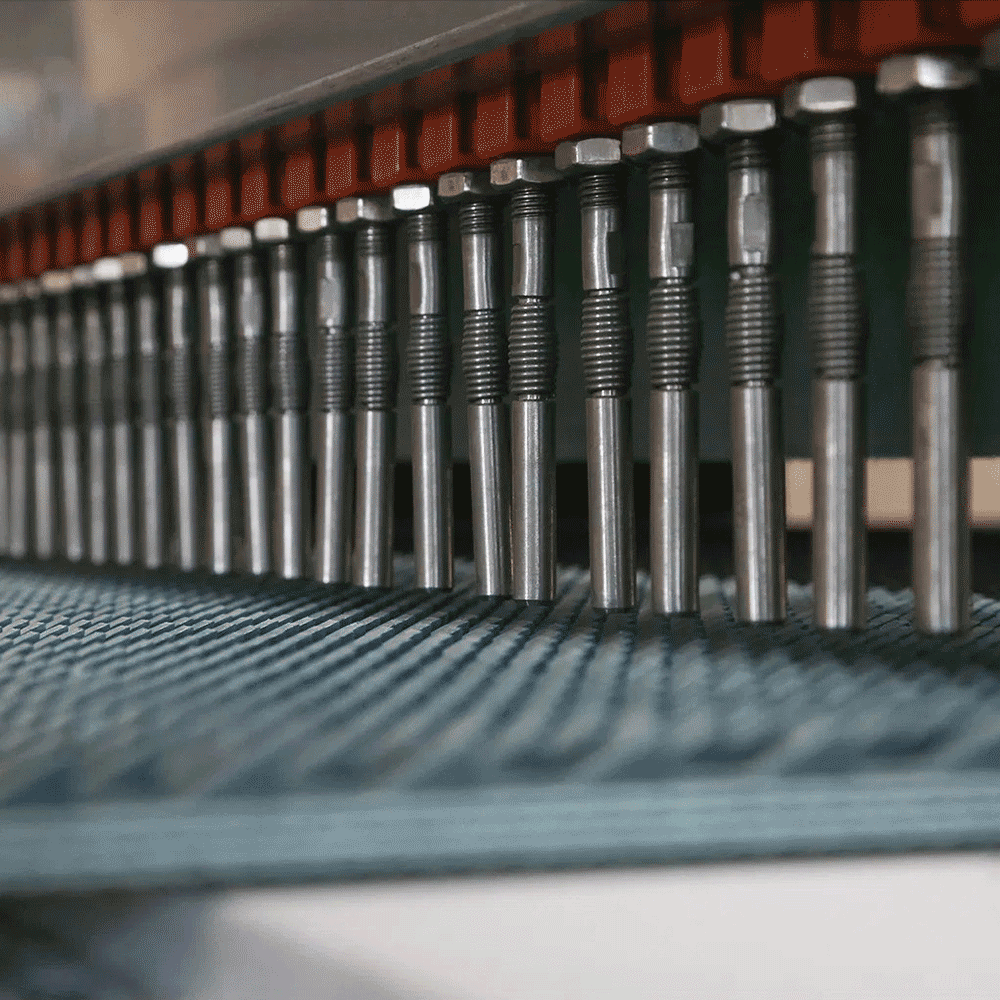

The slab is then transported into the polishing machine, where a row of sensors at the entrance scans its contour and converts the shape into electronic signals.

These signals are processed by a computer to generate a digital profile array of the slab. Based on this data, individual polishing heads are precisely controlled to lift or lower according to the slab’s shape.

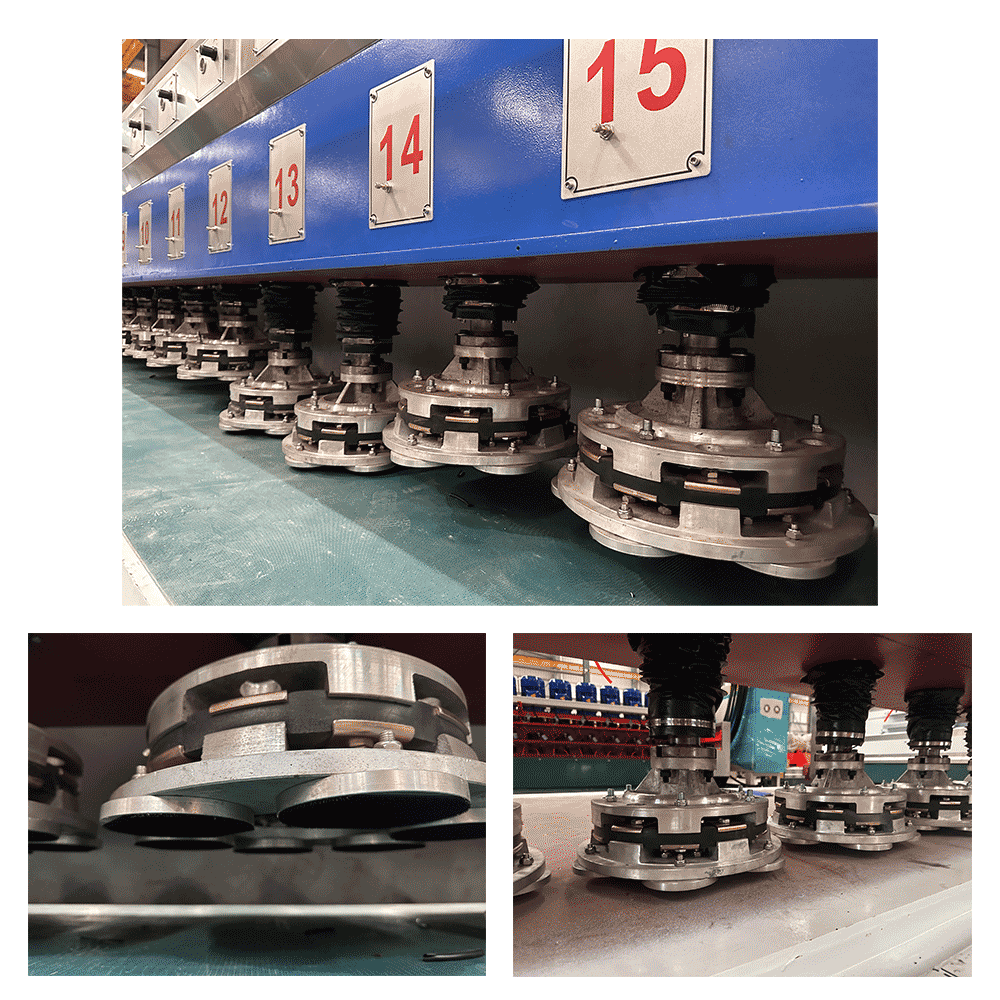

Simultaneously, the beam carrying the polishing heads moves back and forth. The process starts with diamond leveling heads that ensure uniform thickness.

Subsequently, various polishing heads perform step-by-step grinding, from coarse to fine, culminating in a polished finish.

A key feature that distinguishes this marble polishing line from granite processing systems is the addition of drying and automatic waxing stages.

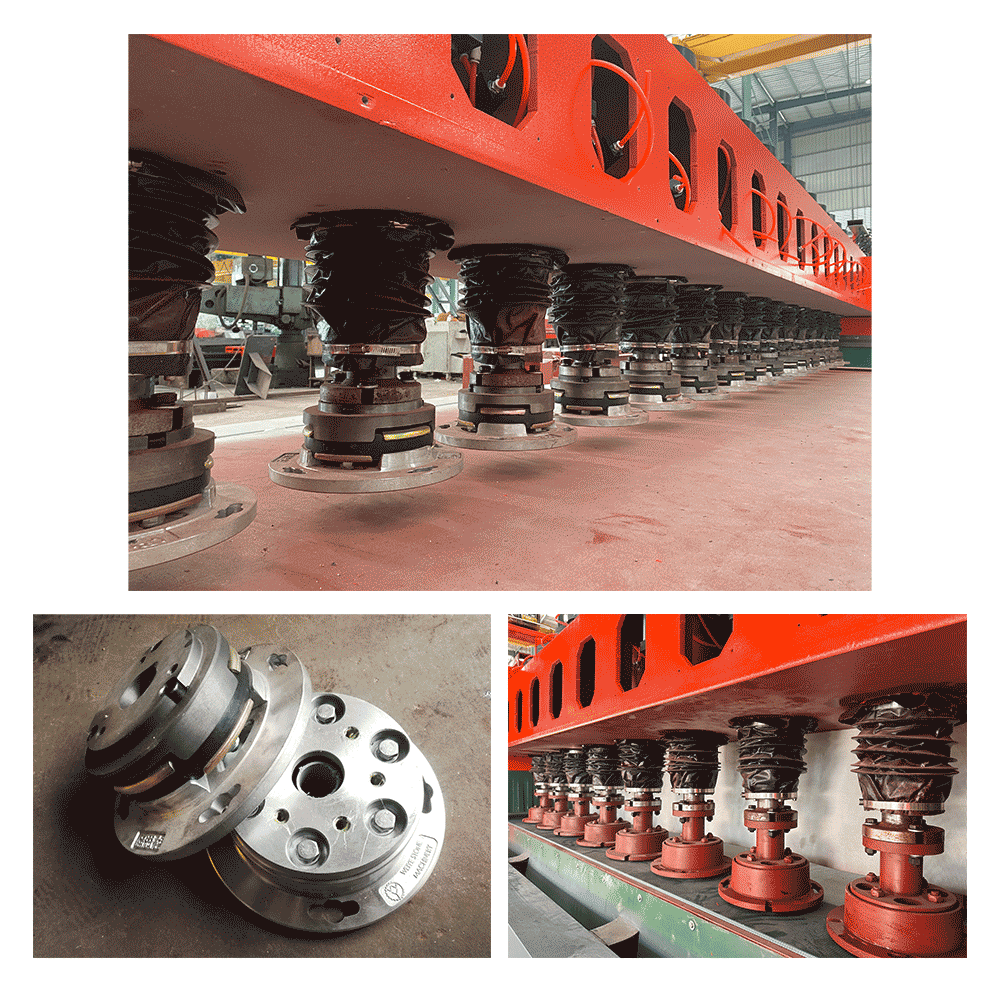

As shown in the diagram on the right, the design of the marble polishing heads also differs from other models. Here, the pressure is applied via pneumatic cylinders, allowing adjustable force depending on the hardness of the stone. The polishing block holders are connected to the polishing head through linkages with rubber sleeves. This assembly enables strong and effective grinding as the head rotates.

The entire process is fully automated, ensuring high processing efficiency and superior finish quality. To date, no other international machinery has been proven to outperform these specialized marble and granite slab polishing systems.